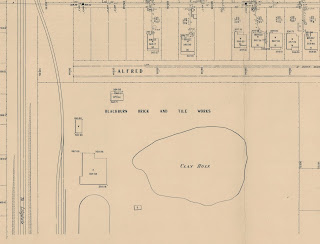

F.A. Harris started a pottery works at Clifton Hill in about 1872 winning awards at the Melbourne and Philadelphia Exhibition of 1875. Three years later he started a new steam powered plant in Raglan Street near Hotham Street, South Preston, which he called the Builders' Brick and Tile Supply Company. The products included flower and chimney pots, fire bricks and pressed white and red bricks. Housing for the workers was provided in Raglan St near the kilns. He initially prospered to the point he could build a substantial mansion 'Baruna' in 1892. However, he was ruined in the depression, his company went into liquidation and in 1895 and Barunah was seized by the Bank of N.S.W.

The brickworks site in South Preston was redeveloped for residential use in the 1930s, with the clay pit becoming Cochran Reserve.

.JPG)

.JPG)